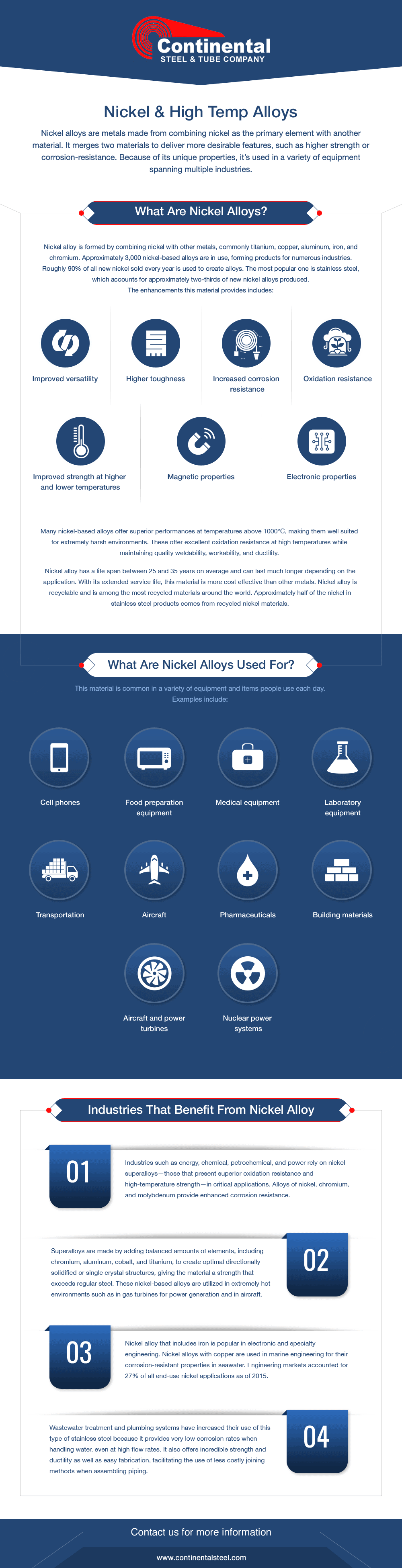

Nickel Alloys

Continental Steel & Tube: Your Trusted Supplier of High-Quality Nickel Alloys Since 1985

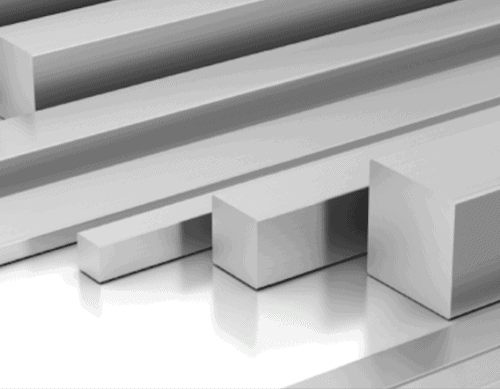

Nickel alloys are characterized by excellent strength, electrical and thermal resistance, low thermal expansion, and corrosion resistance. These properties make nickel alloys suitable for various applications in different environments and operating conditions. Continental Steel & Tube Company supplies nickel alloys in several shapes and forms. Standard options generally include:

- Square nickel bar

- Hexagonal nickel bar stock

- Nickel round bar

- Nickel plate and flats

- Nickel sheet and coil

- Nickel tube

- Nickel pipe

- Nickel strip

- Nickel wire

Our nickel alloy products are available in a range of dimensions as well.

Continental is a leading nickel alloy supplier, with a large selection of nickel-based materials for use in many industrial applications. In addition, we supply specialty and hard-to-find metals and provide value-added services like fabrication, forging, and processing operations.

Learn more about our nickel alloy products and why they are an excellent material for so many applications.

Nickel Alloy Shapes

Nickel Alloy Grades

- Nickel Alloy 20

- Nickel Alloy 155

- Nickel 188

- Nickel 200

- Nickel 201

- Nickel Alloy 255

- Nickel Alloy 400

- Nickel Alloy 405

- Nickel Alloy 600

- Nickel Alloy 601

- Nickel Alloy 617

- Nickel Alloy 625

- Nickel Alloy 718

- Nickel Alloy X750

- Nickel Alloy 800H/HT

- Nickel Alloy 825

- Nickel Alloy 925

- Nickel A286

- Nickel Alloy C22

- Nickel Alloy C276

- Nickel Alloy INVAR 36

- Nickel Alloy INVAR 42

- Alloy X

- Nickel L605

- Alloy K500

- Rene 41

- Waspaloy

The Benefits of Using Nickel Alloys for Your Application

Nickel alloys are created by mixing nickel with other metals, such as titanium, copper, aluminum, iron, and chromium, in different proportions to obtain desired properties and characteristics. They offer many benefits, including:

Industrial Applications of Nickel Alloys

Primary industrial applications for nickel alloys include:

- Aerospace: Nickel-based superalloys can withstand extreme heat, making them an ideal solution for aircraft and engine components and turbines.

- Chemical & Petrochemical Processing: Nickel alloys containing molybdenum and chromium offer enhanced corrosion resistance for applications in chemical processing facilities.

- Energy & Power Generation: Nickel superalloys are often used in gas turbines, power generation turbines, nuclear power systems, and high-temperature applications requiring superior resistance to oxidation.

- Marine: Nickel alloyed with copper is used for components in ships and boats thanks to their resistance to saltwater corrosion.

- Plumbing & Wastewater Treatment Systems: Nickel alloys resist corrosion from wastewater and additives at high pressures. Nickel-based pipes are also easily joined and welded in pipeline systems.

Additional uses for nickel alloys are:

- Construction materials

- Cell phones and electronic devices

- Food processing equipment

- Laboratory equipment

- Medical equipment

- Pharmaceutical manufacturing

- Transportation equipment and vehicles

Related Blog Posts

Find the Perfect Nickel Alloy Solution at Continental Steel

Whether you need a single nickel alloy or a full bill of materials, Continental Steel & Tube Company can help. We are a leading nickel alloy supplier and can also supply specialty and hard-to-find metals including titanium, stainless steel, steel, aluminum, brass, bronze, and their many alloys. We also offer value-added services including cutting, grinding, trepanning, welding for metal structures, metal forging and processing, and exporting. We are AS9120B:2016 and ISO 9001:2015 certified.

Contact us to learn more about our products and capabilities, or request a quote today.

Do you want to learn more about:

- Making your material search easier

- Reducing your lead times

- Eliminating frustrating searches with multiple suppliers

Sign up for Continental Steel product highlights and deals: